if I had more time, I would have written a shorter letter……

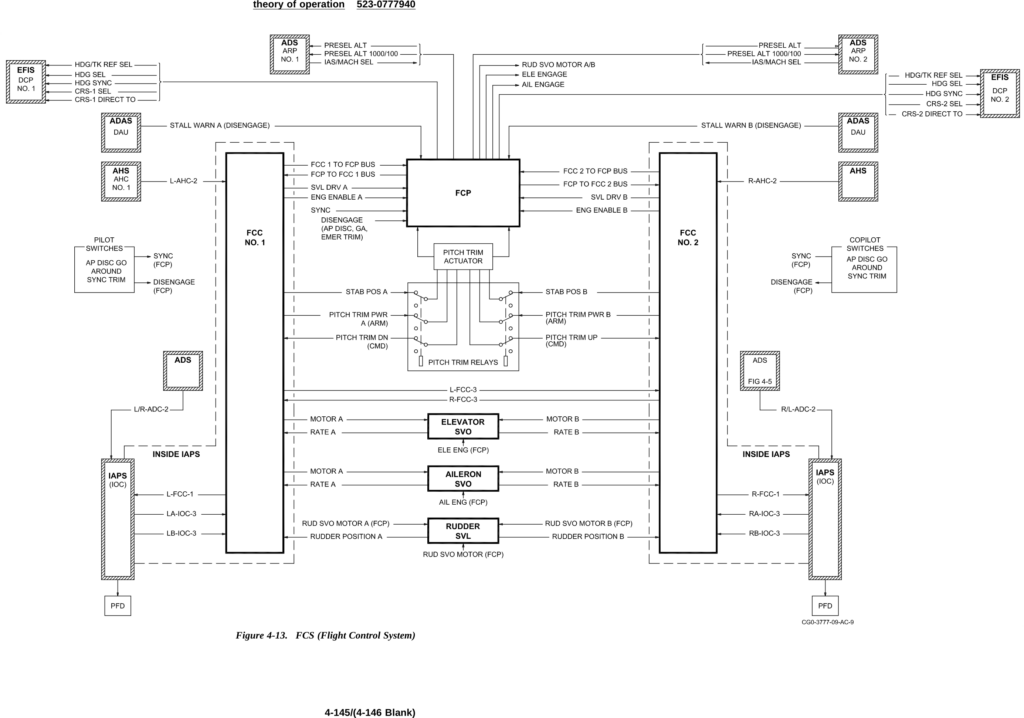

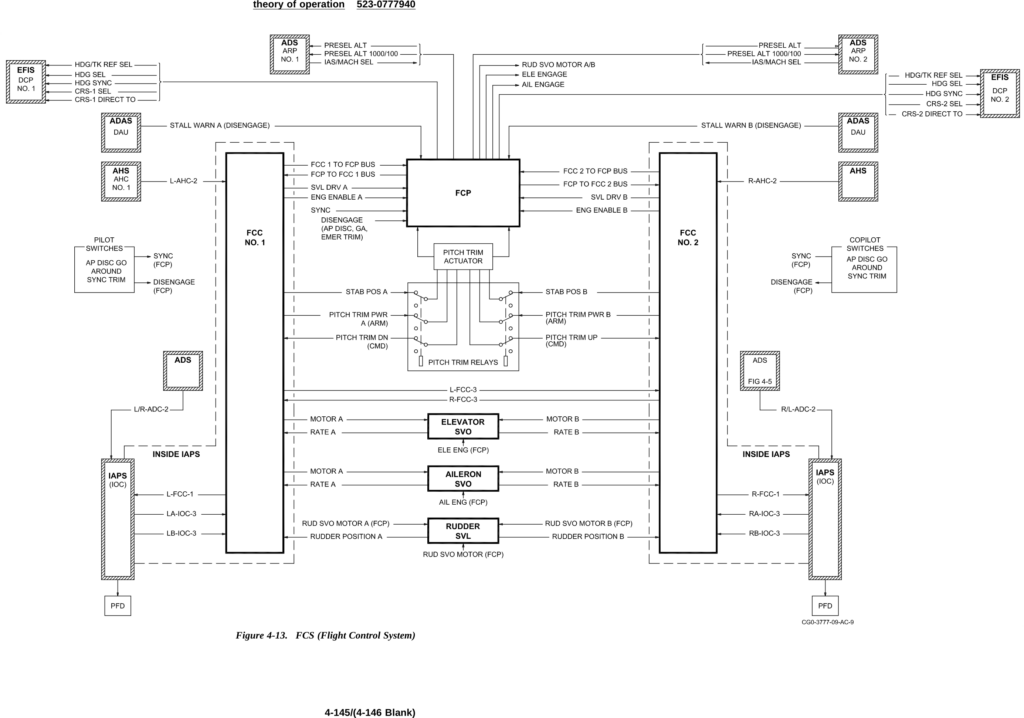

Proline 21 servo drive walk-through

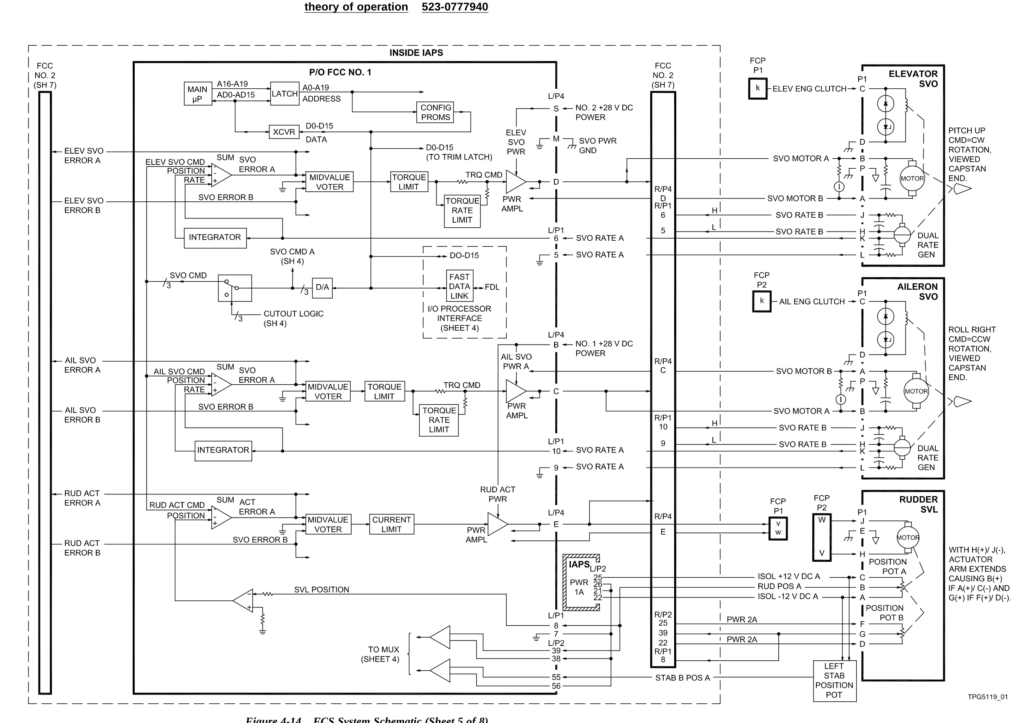

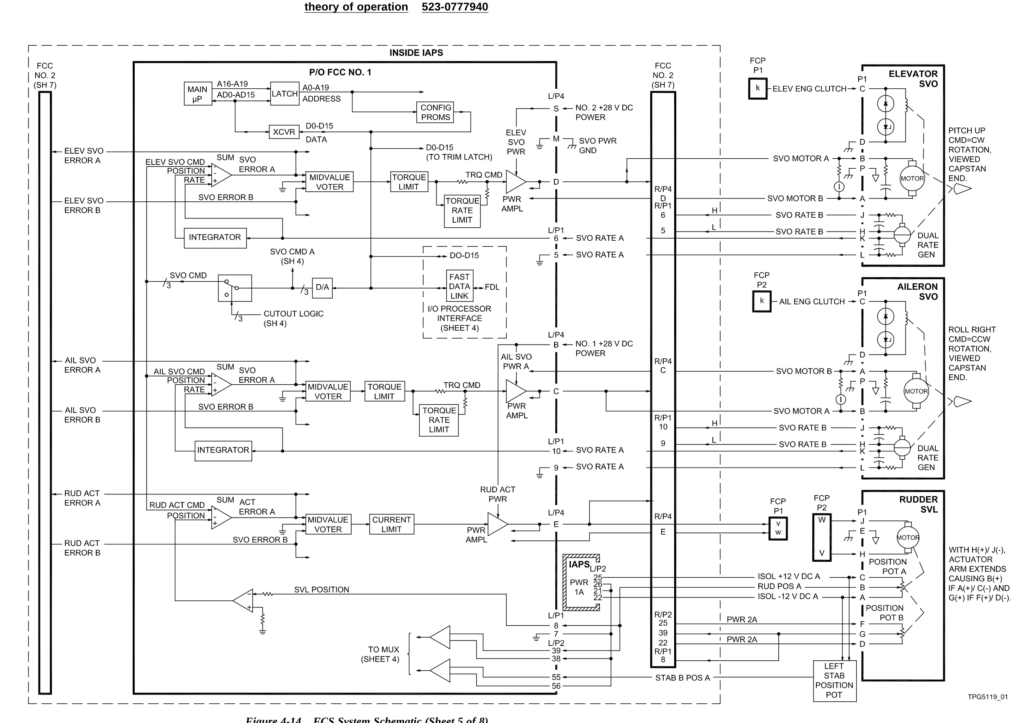

FCC block page519  FC to servo page 535

FC to servo page 535  part of fcc 2page 535

part of fcc 2page 535

Holds Falcon 50 specific troubleshooting information

if I had more time, I would have written a shorter letter……

Proline 21 servo drive walk-through

FCC block page519  FC to servo page 535

FC to servo page 535  part of fcc 2page 535

part of fcc 2page 535

1. Copilot D-bar dissappear intermitantly when LNAV selected, even though AP steers correctly

2. Copilot ALTSEL mode erratic.

3. FD FAIL when VPATH blue button is illuminated.

Verfied copilot ALTSEL mode would activate, even when FD was not displayed. Reacts to harness being manipulated aft and below FGC 2. drill swarf in harness.

Falcon 50. FZ-500

The comparitor circuit exists in both DPU and the MPU.

They communicate about errors

Falcon 50 EFIS 86 comparator and heading

EFIS-86A

EFIS-86C

In a falcon 50, or 200 used DPU-86C

622-7248-001, or -002 after mod

Manual for EFIS-86(1) is

EFIS-86(3) or (13) usses DPU-86L

EFIS-86 (4) or (14) uses DPU MPU86R

In a low SN 50

622-9009-001 or -002 after mod. Is this what gives names on waypoints on MFD?

EFIS-86E

Possible manual

https://gsplanestuff.com/products/collins-efis-86c1-install-manual-using-dpu-86c-mpu-86c

Possible manual

https://www.ebay.com/itm/183819877377?hash=item2acc84bc01:g:43YAAOSwLGVc5DJM#shpCntId

Target the gear to get WOW

Disconnect the down brace prox (2 on each) to get GEAR NOT DOWN.

Disconnect RA RECV coax cable to get RA 2500 FT.

observe RA 2500 FT on the ADI

Select FID on TXP