Continue reading How can I troubleshoot a yaw damper on the ground?

Category Archives: F900 Troubleshooting

Holds Falcon 900 specific troubleshooting information

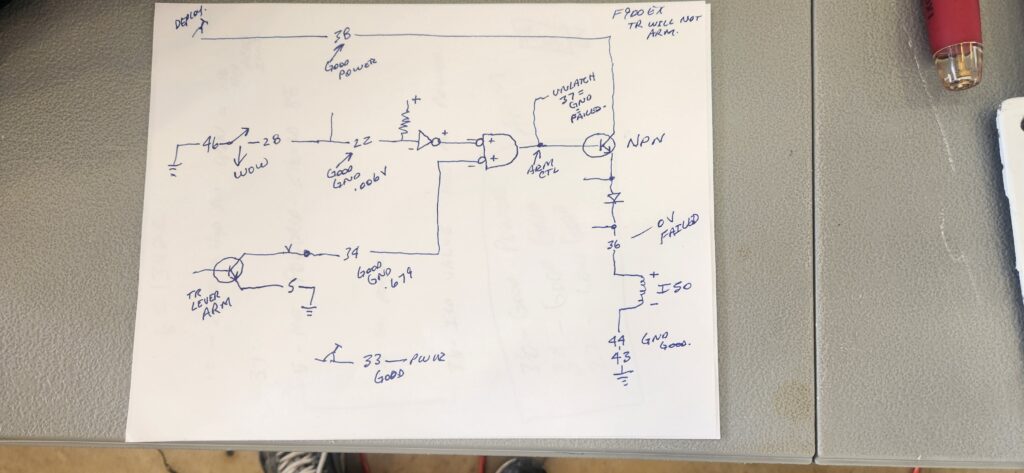

F900EX Thrust Reverser will not open

Throttle lock works. Red TR UNLOCK annunciator works.

No green words in the n1 gage.

Pin 22 is 0V on ground, 28v when both mains in the air. all good.

F900lx Power up , By the CODDE

F900 Stab trim normal will not run in either direction

TL;DR Turned out to be bad stab jack, installed in the airplane for less than 2 years.

F900EX

customer reports he can hear the main relays click… no up or down, no report on the autopilot.

Note, thus is the HStab jack that has internal normal limit switches. The other stab jacks have external limit switches in 4 CF.

print PDF

PowerPoint print so that you can draw on it. (LibreOffice Impress)

Falcon Flies Fine now! Aileron Author follow-up arm broken in two.

F900ex fuel qty erratic

Thrust Reverser harness, F900ex harness ringout

Capacinno maker F900EX SN 001

F900ex SN 001. Missing wire diagrams

1. CPDLC , FANS 1A, and associated CVR upgrade.

2. IOCABUCCI espresso machine upgrade. Need at least parts list of plumbing.

3. ? Elt upgrade?

4. DU875AF display upgrades.

5. WR 870 Upgrade, PROSTAR aviation.

6. CDU-820(?) Upgrades. 3 FMS CDUS are upgraded, no prints.

7. Davtron clock upgrades

8.