We replaced all 8 connectors.

Luis

Aeropainting

972 757 8980

Pycharm

pycharm-community in the command for the gui

All slats, flaps, and fixed LE removed.

Support lollypos .

All actuators to retract.

Lube all cables if applicable.

Do not connect drive cables to {DU.

Remove actuators, measure on bench, at retract position. Adjust lollypop.

Install actuators

Set outboard actuators to retract dog stop voltage. turn pollypos to full retract position. Vertical within 5 degrees?

Cut safety wire and adjust lollypos to vertical. Safety wire.

Measure actuator retracted length again.

if within specs, support jackscrews.

Remove C1 to allow brake release.

Brake release. 9 1/2 turns out for slats by speed handle. 24 out for flaps. !!!!!!! turn brake release off.

Verify PDU is DISCONNECTED from inboard drive cables.

RAC PDU down a little, then up tp UP ELECTRICAL stop.

Connect C1

Connect inboard cables to PDU.

Be sure the Jackscrews are supported, and CANNOT touch the internal fuel cups.

RAC to full extend.

Test degrees of over rotation is allowed to get to the dog stop. return to vertical. install fixed LE. Install Flap Slat.

RAC to retract. recheck retract RAW RETRACT voltage.

Check Conditioned retract voltage. adjust to book value.

RAC to extend. Check conditioned extend voltage.

Check intermediate voltages

Winxp only

Bring dump card and clean data card. Smaller than 256mb. Formated fat 16. .( FAT)

Pull cb reer d3

Door will not open till power off

Eject card

Insert dump. Leave door open. Push cb Be paitient.

Wait for complete light.

Pull cb

Insert empty data card.

Expect CHECK MDAU nuisance message.

Win xp explorer to copy to compuTer folder

USE MDAU_READOUT 7.0

FORMAT one.

Make one dump.

Current as of Nov 1 2025:

Bus A has sawtooth only when DCU1 breaker pushed.

Bus B has sawtooth only when DCU 2 breaker pushed.

Here is failure mode, showing shorter, sawtooth pulses:

Here is non-failed mode, square pulses:

Very infrequently, the sawtooth will be very pronounced.

We have been warned the the pulses must be 3.5v Peak to Peak. Our good pulses show 3.1v, and the runt pulses from the DCU show 2.1v. Some inaccuracy expected because we are using a 6 foot scope probe, off of a bus tap mid string. If we sampled at the terminator, both would be slightly higher?

Here is the original F900 ASCB topology, with Universal pin numbers annotated.

??=====================================

Current as of oct 31, 2025

The frequent un-commanded disengage comes with LAFCS FAIL, and B16: Servo interface monitor fail on the bit codes

Occasional IRU DATA INVALID.

Occasional Disengage ANN data fault

Not sure about this one:

Initial problem.

AP transfers, AP uncommanded disconnect random, only in flight. MTRIM and YD disconnect most of the time.

+++++++++++++++++++++++++++++++++++++++++++++++++

Older printable data:

34-09-01-A.S.C.B WIRING page 1  34-09-01-A.S.C.B WIRING page 2

34-09-01-A.S.C.B WIRING page 2

ASCB cropped 3 pages Printable

Free pickup drop off 76078

Mark Patnode

2146976225

A and P , was IA.

if I had more time, I would have written a shorter letter……

Proline 21 servo drive walk-through

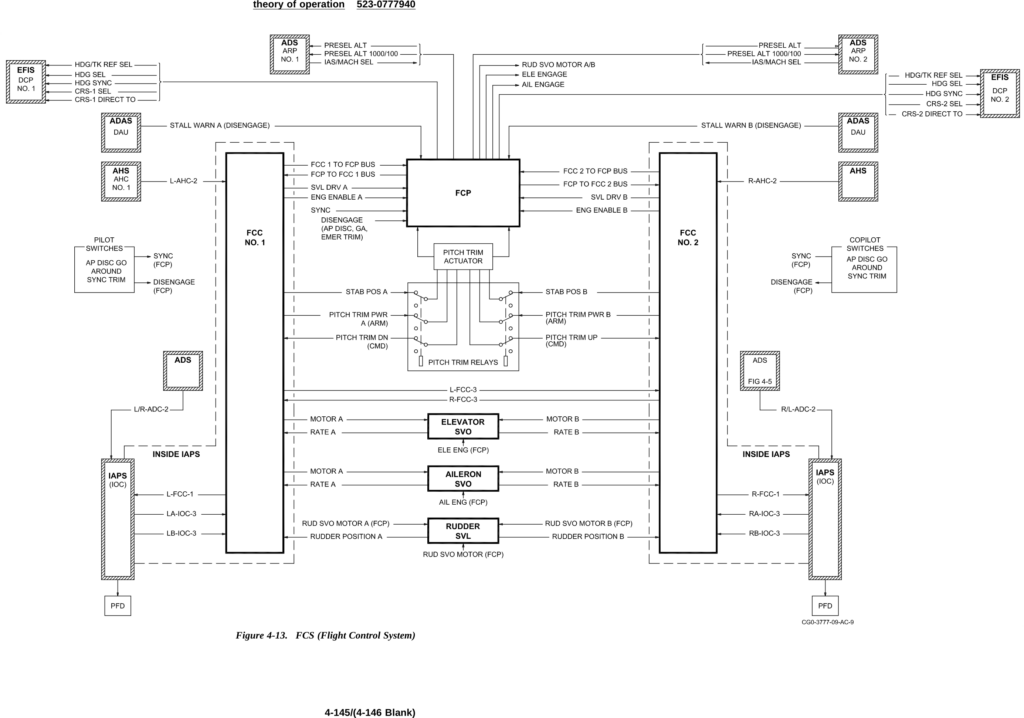

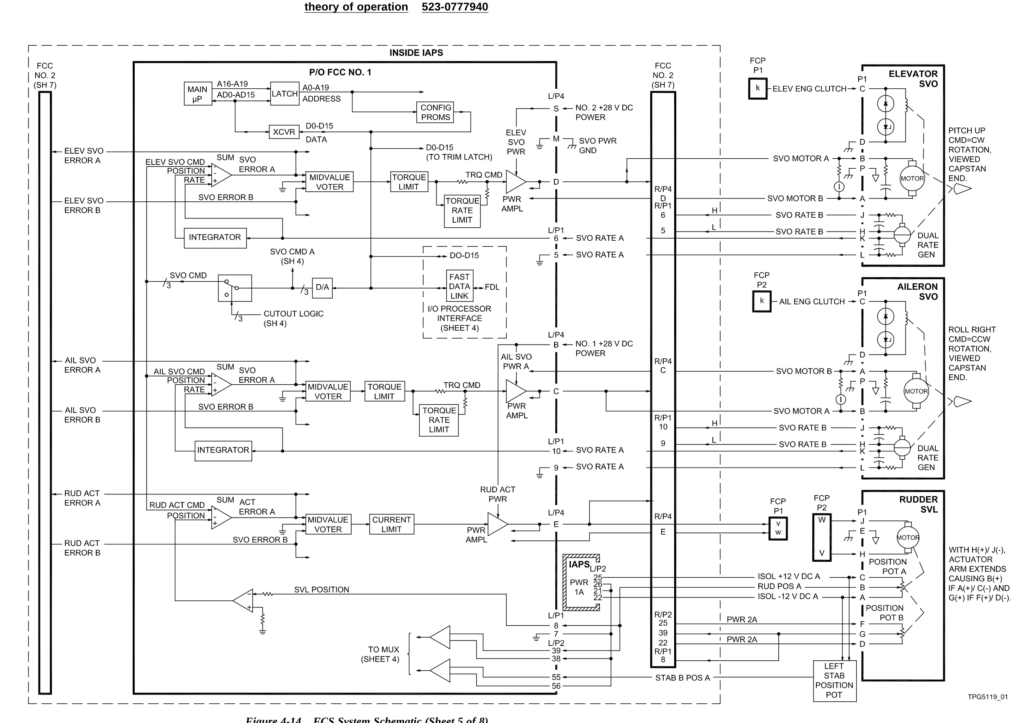

FCC block page519  FC to servo page 535

FC to servo page 535  part of fcc 2page 535

part of fcc 2page 535