Cockpit:

Pitch feel light – 1. Trim out of range, no hydraulics applied

2. Amp at MED is VERY hard to engage.

Habitual bleed control red meneco.

1. SOMETIMES associated with bleed 3 fail.

2. On low serial number 900ex….. always power up both A an B bus at once.

IRU ALIGN slow flash after 10 seconds. – low battery.

IRU ALIGN fast flash after 8 minutes. – initialize FMS again

Half of the Cabin overhead lights in the cabin off – switch near FSB/NS

Auto slat light – Avionics Master, WOW,

St by pump light stuck on – Red Handle out of position

Ail feel light on. Avionics masters.

Operational:

No Airspeed on T.O. – Bugs in pitot,

Black Pitot Masts – Pilot heat on on ground Service Letter about plating inside the mast. DO NOT REMOVE THE MAST until you read and understand the letter

Baggage door will not close. – Cash Logic,

Step switch bent.

Jacking ac with stby horizon – Pull Breakers, or disconnect proxes !!!!PRIOR!!! to jacking. Once you are on jacks, Think carefully about how to disable the stby horizon

Service ladder aft compartment is scalding hot after extended ground run. – Close cabin door and DV window during extended ground run. Max cold on both packs. The cool air out the outflow valves cools the MSC just fine.

Long ground apu run results in: #2 Deec Manual Mode, Warm Bat, Removable Step ladder scalding hot, APU Un-commanded Shutdown – MED and DV window must be CLOSED for long ground runs.

Entry door cabin lights sw.

No logo lights. – when on jacks, they are a load shed item.

Baggage light inop. – Let baggage door open quickly.

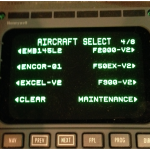

NZ 2000 ACDB after memory bat change – reload the ACDB, its in the nav data USB

NZ2000 hyperstart.

Nz2000 selected dual operates single – First thing to try is crossload Custom DB.

Low fuel 2 light on early during fuel transfer. normal. electric pumps outrun jet pumps.

Fuel 2 level light on early during flight. – nuisance

Ail feel light – Avionics Mater

Antiskid menelco resetable , water in Nose gear axel, one nose bearing tight.

Antiskid menelco not resetable. Nose harness towing disconnect

Antiskid fails to test on ground. – ITS ALWAYS SOMETHING IN THE NOSE GEAR. almost always.

Antiskid fails test in air – Main gear tachs

Red antiskid occurs near the end of the flight – do not test AS while gear is in motion.

Fueling ok light will not illuminate – first questions: Courtesy Lights on the fuel doors?

Aircraft will not take fuel – STBY horizon test button? – Full/Partial

Fresh water stinks -Use Purogene and citrus like the manual says

Fresh water will not take water. – broken cable

Nose steering inop.

Nose harness connector in nose wheel well ceiling is very hard to snap.

GPU start causes dramatic electrical blackout.

Think carefully about the relationship of the EXT switch and the GPU small pin power. Battery Red switches on. Normal Power selection first, aircraft voltage settles to 24v, then disconnect GPU.

Generators off line during Gpu start – Uh….OK.

One battery refreshes quickly after the start , one takes a long time to charge.

1 engine generator offline during taxi out – Hot APU GCU runs a little high. Stop APU.

Turbo fan menelco turns red.

Water drips out of belly – Oopsie. cracked line at right hand cabin (floor level in a 50, PSU level in a 900)

Water drips out of PSU and pours on VIP’s head!

1. Water pipe frozen and burst

2. Water sock freezes, and popoff opens. injects LOTS of water in the ducts.

Switches in aft compartment has gooey hydraulic fluid –

OK for old style , 1 inch diameter switches

Fitting in nose well has drips of hyd fluid –

Roll Q swivel seals. is it old and stickey, or new and dripping?

“AP unavailable wow” message – Uh….OK.

Wx FSTBY on ground –

Push STAB button 4 times, ONLY for 880 radar.

If you have a 870 radar, you have bigger problems.

Wing will not clean up using stby pump –

Learn about Red Handle.

Flap CB. pops – Fishing reel sat outboard flaps get sticky.

Hyd pump growls after engine start-

1. Bleed return line.

2. Collapsed intake line. teflon liner tears away from hose

Engine computer light slow flash DEEC – downlod deecs

MED lower step feels mushy –

wrong hardware at handle pivot on door

MED pops on climb –

Stops have grey smokey spots, not lubbed

MED Heavy – How long is the barrel on the counterbalance arm?

Nose cone pops on climb –

1. sticky flapper actuator,

2. stickey o’pressure popoff,

3. Figure out radome drain, plunger drain, holes in flapper, See (several) service bulletins

Masks drop on climb – Condition switches left off during climb

Splits on RVSM checks – Rudder trim changes as AC cold soaks.

“TRIM RIGHT WING DOWN” trim required on long cold soak –

Pre Mod airplane

Avionics Maint required – 900EX – Cable and DLC software

Ail feel light – Avionics master

Can’t find entertainment breakers – 900Ex Aft Toilet RH wall

900B – AFT baggage LH wall

Apu will not start –

WOW, Bus Tie, Green square GEN button

APU STOP button has no internal lights

Engine will not start. WOW, BUS Tie, red GEN sw, throttle cuttoff,

Engine 1 runs cool – HP VALVE

Have -Job/No-Have-Job switch –

Wing Heat switch is UNFORGIVING

Engine 2 light on – latches on S Duct door

Stby horizon battery will not test –

1. WOW,

2. Unbalanced battery pack.

No ITT rise on 1 engine – HP valve only on #1

Engine 2 light on momentarily when throttle is advanced –

1. Uh….OK on a B model

2. failed PC card on a EX

PRV test shows no it rise – don’t test PRV with APU air on.

No green lights on Airframe or engine 2 ground test –

1. takes LOTS of power to get green lights.

2. NEVER USE THE APU BLEED to test heats.

Red cabin light stuck on. leather on MED upper hooks

Number 2 Engine start is much slower / hotter than 1 and 3 –

Battery only #2 start after 5 min of APU run.

1 gen light comes on and another red sw pops –

1. Its not a GEN 1 problem

2. The FIRST gen light you see is usually the GOOD Gen!

Landing lights pulse without warning – TCAS Auto feature

EFIS Test not available, engaged – Turn off MTRIM

Fuel flow digits do not react to the throttles – they indicate consumed fuel.

Fire Test Causes APU shutdown – Troubleshoot APU FUNCTIONS circuit card

Intermittent BAG FIRE horn. 900ex only. The Stby horizon battery 2ND OUTPUT! Drives the test for the baggage smoke detector circuit. It can be failed even when the stby horizon tests good.

Noises:

MED Bump during climb – MED Stops are grey.

Loud clunk under pedestal as throttles are advanced – #2 Brakes Dual Braking arming, normal.

Nose cone bump during climb . Fan Valve

Singing at mid cabin – Sirenage, P.brake O’pressure valve bypassing

singing during cruise –

Sirenage – apply wing heat and see if it changes

Try rudder pedals, vertical stabilizer cuffs.

thumps during taxi – Nut on main gear

clanking noise from pedistal during taxi – nose door, normal.